Rapid prototyping with mucision

Experience our rapid manufacturing solutions, including CNC machining, injection molding, sheet metal fabrication, 3D printing, and vacuum casting services, delivered with unparalleled precision and lead times as short as just one day.

What is Rapid Prototyping

Our Manufacturing Capabilities

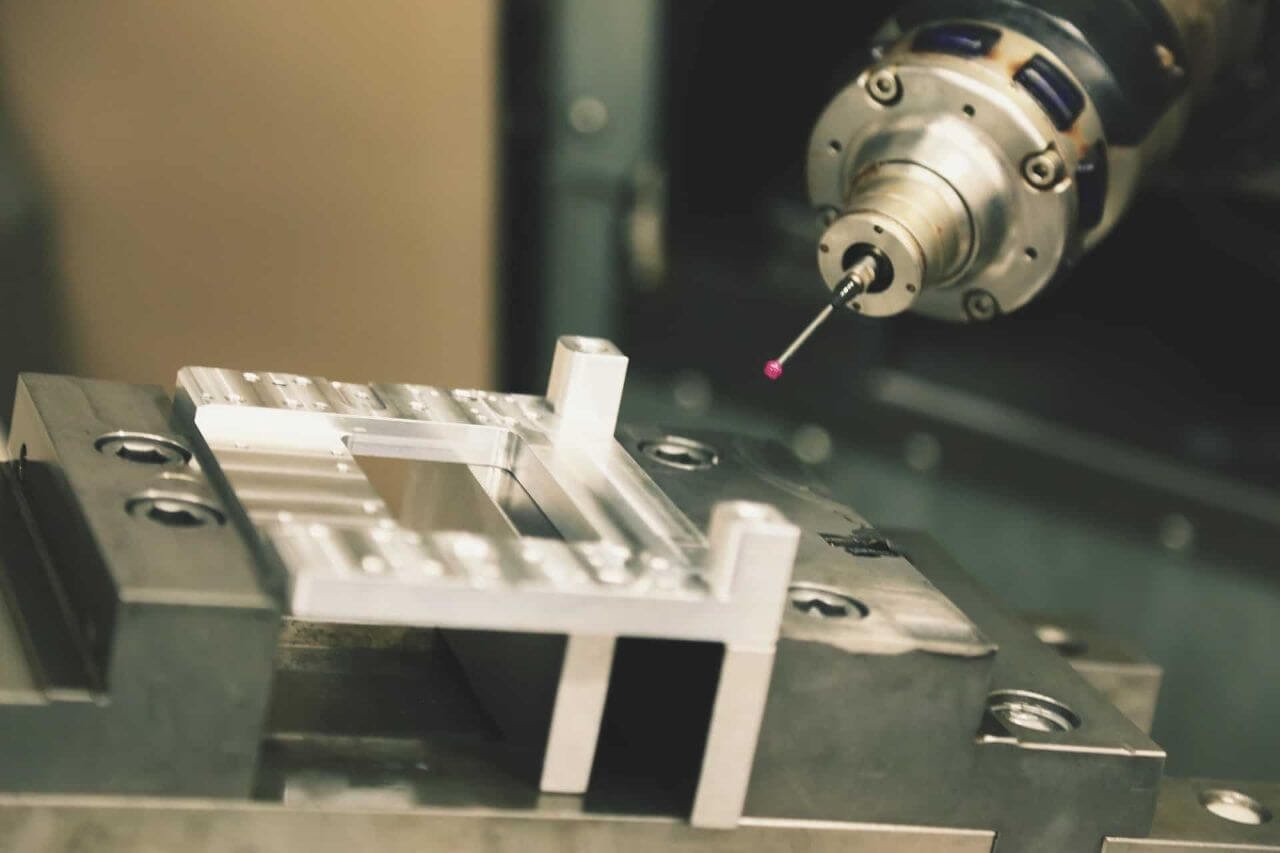

CNC Machining

Unlock unparalleled precision and intricate designs with our advanced CNC machining capabilities, perfect for complex prototypes and high-performance components.

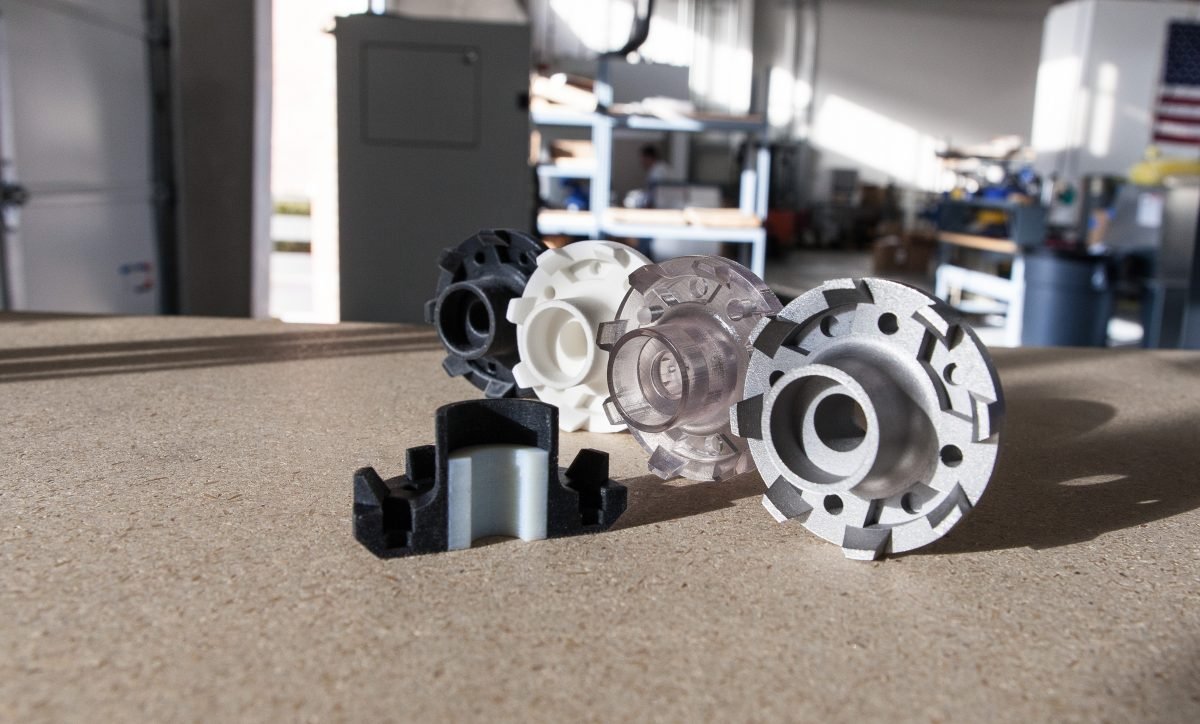

Injection Molding

Elevate production efficiency with rapid, high-quality molded parts and bridge tooling solutions, expertly tailored for large-scale manufacturing and unparalleled product consistency.

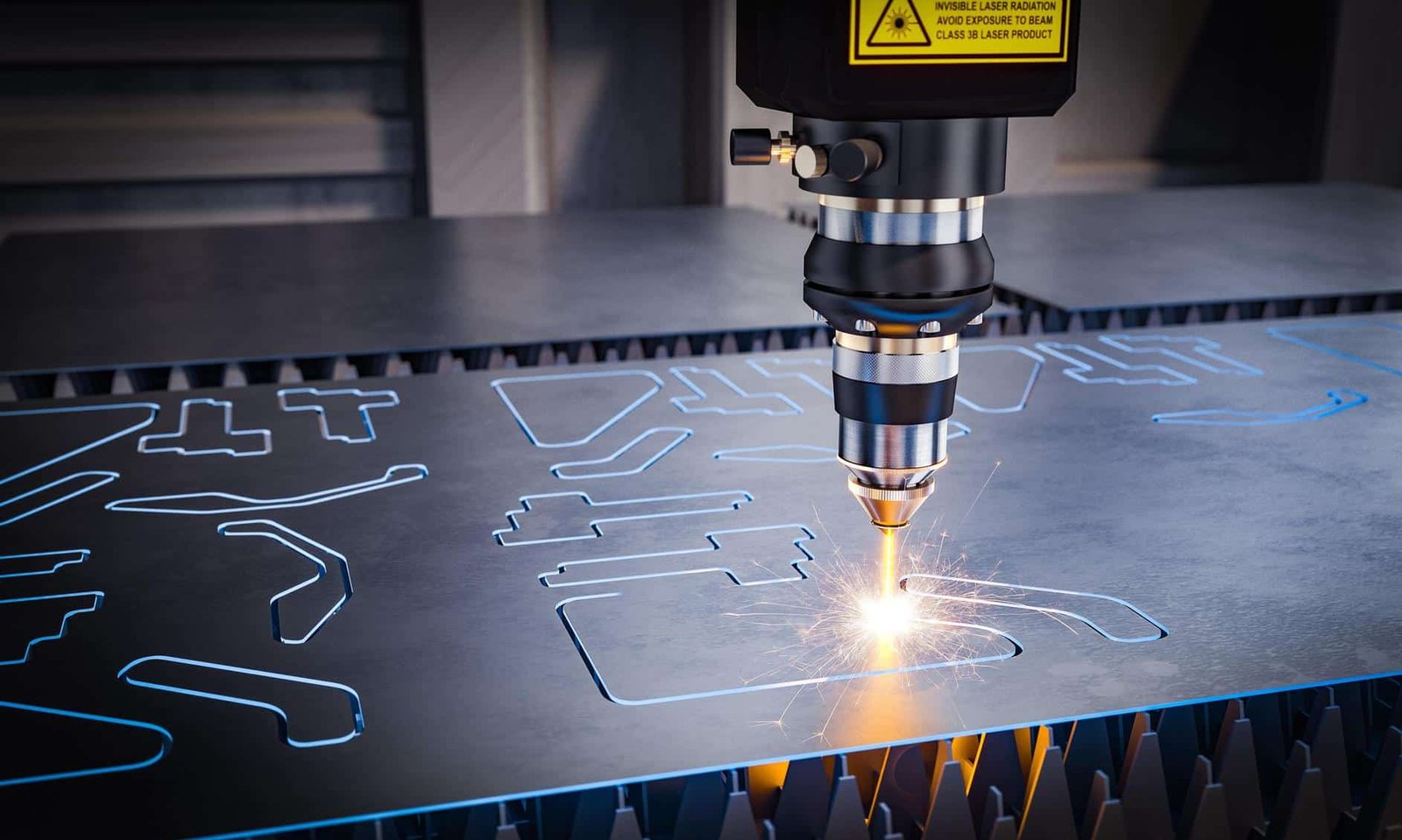

Sheet Metal Fabrication

Experience unparalleled adaptability and precision in shaping metal components for diverse applications, harnessing the versatile power of metal forming.

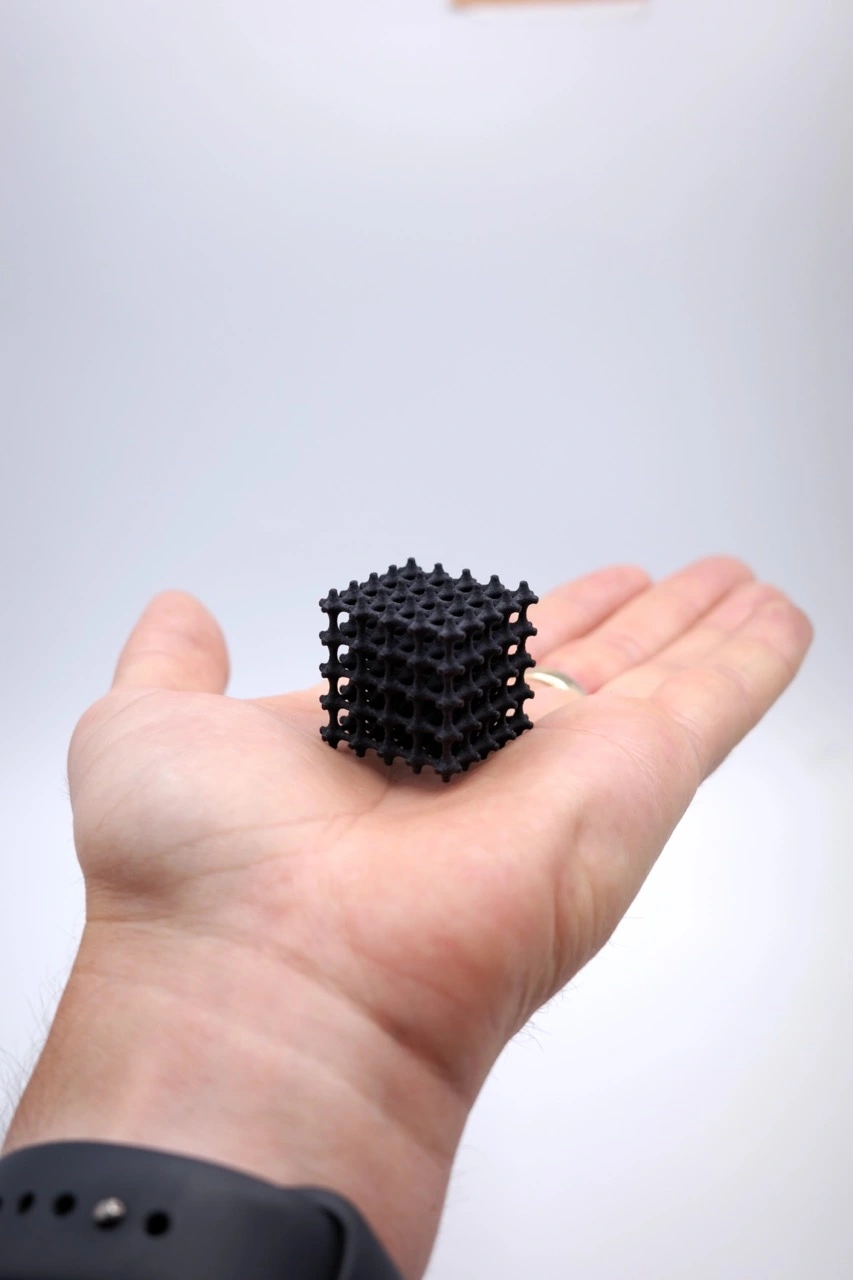

3D Printing

Rapid and adaptable, this technique effectively transforms a wide range of materials into intricate shapes, ideal for pioneering and imaginative designs.

How to Between Rapid Prototyping Processes

For engineers and product designers seeking online rapid prototyping services to accelerate product development cycles, Mucision provides an array of rapid manufacturing processes designed to create prototypes efficiently and cost-effectively. While there are numerous methods to produce any given prototype, it is ultimately the engineer’s responsibility to determine the most suitable process and material for their product.

Recent advancements in additive manufacturing technology have propelled 3D printing to the forefront of rapid prototyping solutions. As parts can be printed quickly, affordably, and in various metals and plastics, 3D printing has become the preferred choice for engineers seeking speedy prototype creation.

Rapid 3D Printing Processes

For engineers and product designers seeking online rapid prototyping services to accelerate product development cycles, Mucision provides an array of rapid manufacturing processes designed to create prototypes efficiently and cost-effectively. While there are numerous methods to produce any given prototype, it is ultimately the engineer’s responsibility to determine the most suitable process and material for their product.

Recent advancements in additive manufacturing technology have propelled 3D printing to the forefront of rapid prototyping solutions. As parts can be printed quickly, affordably, and in various metals and plastics, 3D printing has become the preferred choice for engineers seeking speedy prototype creation.

Rapid CNC Machining

CNC milling and CNC turning are excellent rapid prototyping choices for parts requiring evaluation in their final material when cut from fully dense stock. Mucision can machine various metals and plastics, with many CNC machined parts produced and shipped within a week. Expedited CNC options are available upon request, and Mucision’s cost-effective, market-based pricing allows engineers to order multiple prototypes simultaneously for accelerated product evaluation.

CNC machined parts typically have longer lead times compared to 3D printing due to additional machine setup and operation time. In contrast, 3D prints undergo a streamlined direct digital manufacturing process, minimizing setup requirements and post-processing steps.

Rapid Sheet Metal Fabrication

Rapid sheet metal fabrication is an ideal solution for quick-turn flat parts that need prototypes evaluated in their final metal material. With a turnaround time of a week or less, this cost-effective process often allows for the parallel production of two or more prototype designs. While Aluminum 5052 is the most popular sheet metal material for rapid prototyping, Mucision also offers various alloys, including steel, copper, and stainless steel.

Rapid sheet metal parts have lead times similar to rapid CNC machined parts but longer than 3D printed parts. Like CNC machining, sheet metal fabrication requires extra machine setup and operation time.

Rapid Injection Molding

Rapid plastic injection molding generates a robust set of identical parts suitable for testing, providing multiple backup components. Ideal for high-fidelity product evaluations and bridge tooling for temporary production at launch, rapid injection molding typically has a 2-3 week lead time for initial parts. With Mucision’s Quick-Turn Molding option, parts can be ready in just five days. Rapid molding may surpass additive manufacturing or machining methods due to specific material requirements or mechanical properties unattainable by those processes.

While slower than 3D printing or CNC machining, rapid injection molding proves crucial when a higher volume of parts near their final geometric form is necessary. Injection molding excels in producing consistent, repeatable parts with precise shapes.

Why Choose Mucision?

Boundless Options

Select from an extensive range of material, finish, tolerance, marking, and certification combinations to customize your order.

User Friendly

Enjoy convenient, hassle-free delivery of your parts directly to your doorstep, eliminating sourcing, project management, logistics, and shipping concerns.

Enriched Network

We are ISO 9001:2015, ISO 13485, IATF 16949:2016, and AS9100D certified.