Custom Online Laser Cutting Services

Custom Online Laser Cutting Services

Precise laser cut parts for rapid prototyping and production. Free laser cutting quote with DFM review within 1 day. Lead time as fast as 3-5 days.

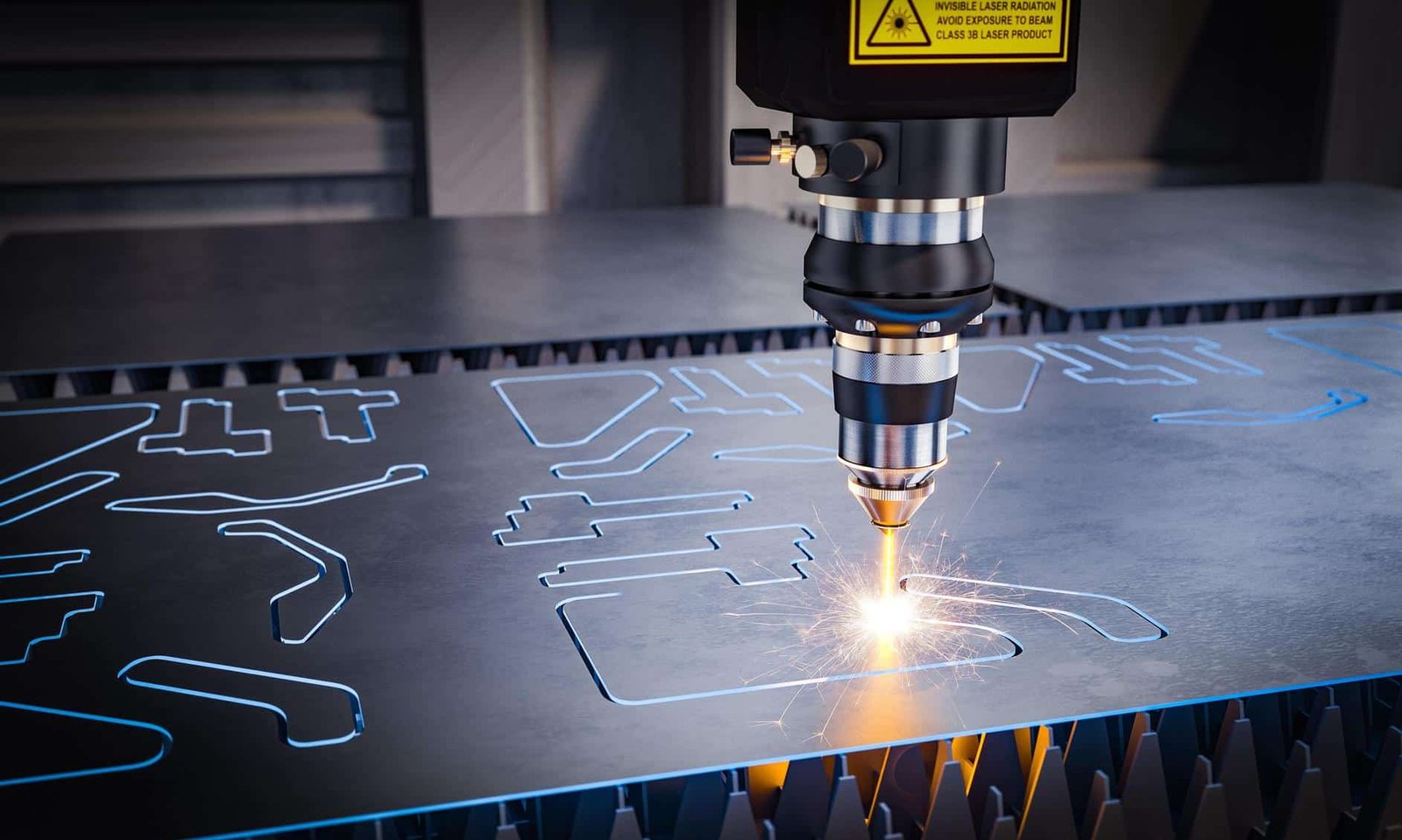

High Quality Laser Cutting Service

Mucision provides an online custom laser cutting service for metal, plastic, rubber, foam, and wood materials. Our on-demand and cost-effective laser cutting solutions cater to diverse manufacturing requirements, from single prototypes and low-volume production to batch and high-volume production runs. Our versatile service supports various materials, including numerous metal and plastic types, acrylic, rubber, foam, and wood.

What is Laser Cutting?

Why Choose Mucision for Custom Laser Cutting?

Boundless Options

Select from an extensive range of material, finish, tolerance, marking, and certification combinations to customize your order.

User Friendly

Enjoy convenient, hassle-free delivery of your parts directly to your doorstep, eliminating sourcing, project management, logistics, and shipping concerns.

Enriched Network

We are ISO 9001:2015, ISO 13485, IATF 16949:2016, and AS9100D certified.

Laser Cutting Services for Various Materials

Mucision Laser Cutting Capabilities

| Description | |

|---|---|

| Maximum Part Size | 10 mm (0.40 in.) |

| Minimum Part Size | 2X material thickness with a minimum of 1 mm (0.04 in.) |

| Distance Dimensions | Our laser cutting standards depend on ISO 2768-c. Typical size: +/- 0.2 mm (0.008 in.) for length, width, diameter and location. |

| Maximum Material Thickness | Carbon steel < 25 mm (0.98 in.), Stainless steel < 15 mm (0.59 in.), Aluminum < 15 mm (0.59 in.) , Copper < 12.7 mm (0.5 in.) |

| Kerf (slit size) | About 0.5 mm (0.02 in.) |

| Edge Condition | Laser cut edges have matte and vertical lines. |

| Laser Sources | CO2 and fiber lasers. Up to 10 kW. |

| Reapability | +/- 0.05 mm (0.002 in.) |

| Positioning Accuracy | +/- 0.10 mm (0.004 in.) |

| Lead Time | 5-7 days |