Mucision’s Die Casting Service

① Start A Quote

Submit your files to our Quote system and tailor your project settings. Our team will collaborate with you to ensure your project requirements, lead time, and budget are aligned. Before initiating tooling, we will provide a DFM report for your approval, ensuring a smooth and efficient process.

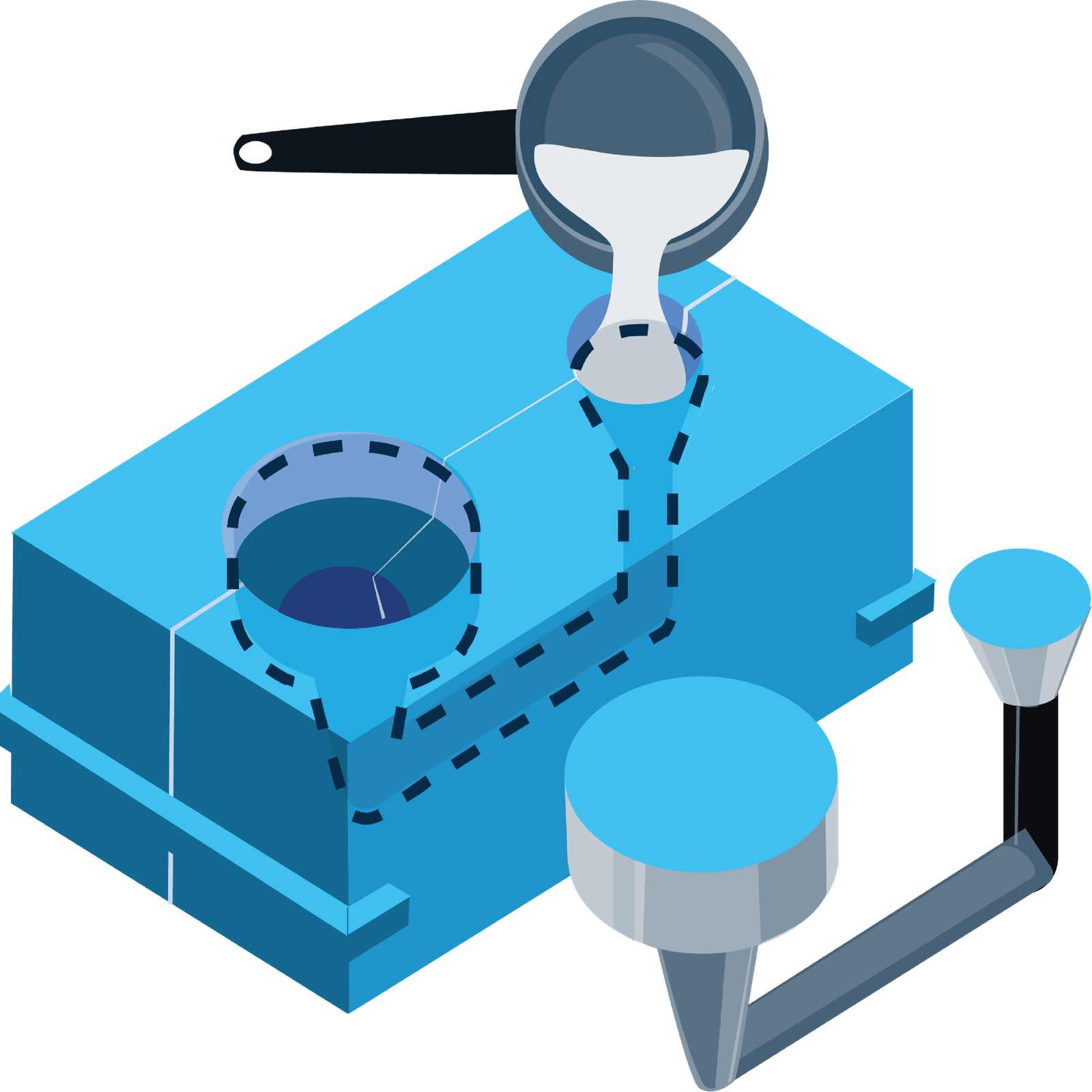

② Sample Approval

Upon project initiation, we will construct a top-quality die. After tooling completion, we will send part samples, referred to as T1s, for your review and approval to ensure the components meet your specifications.

③ Production Begins

When you are content with the part samples, we proceed with full-scale production and deliver the finished components. Mucision handles supplier management and logistics throughout the process, providing a hassle-free experience. You retain ownership of the tooling, allowing for convenient reordering as needed to meet ongoing demand.

Applications of Die Casting

The adaptability and high production capacity of die casting make it suitable for diverse applications across various industries. Die casting is ideal for small to medium-sized products with intricate features, such as consumer and industrial products, automotive parts, aerospace components, and medical device parts. When high-volume metal parts are required, but are too large for processes like Metal Injection Molding (MIM), die casting is a viable alternative.

Why Choose Mucision for Die Casting?

Boundless Options

Select from an extensive range of material, finish, tolerance, marking, and certification combinations to customize your order.

User Friendly

Enjoy convenient, hassle-free delivery of your parts directly to your doorstep, eliminating sourcing, project management, logistics, and shipping concerns.

Enriched Network

We are ISO 9001:2015, ISO 13485, IATF 16949:2016, and AS9100D certified.

Die Casting Types Available at Mucision

Available Die Casting Finishes

Mucision Die Casting Capabilities

| Description | |

|---|---|

| Minimum Part Weight | 0.017 kg |

| Maximum Part Weight | 12 kg |

| Minimum Part Size | ∅17 mm × 4 mm |

| Maximum Part Size | 300 mm × 650 mm |

| Minimum Wall Thickness | 0.8 mm |

| Maximum Wall Thickness | 12.7 mm |

| Quality Control | ISO 9001 Certified |

| Minimum Possible Batch | 1000 pcs |