Production Services by Mucision

Experience our rapid manufacturing solutions, including CNC machining, injection molding, sheet metal fabrication, 3D printing, and vacuum casting services, delivered with unparalleled precision and lead times as short as just one day.

Mucision Scales Your Demand

Our Manufacturing Capabilities

CNC Machining

Unlock unparalleled precision and intricate designs with our advanced CNC machining capabilities, perfect for complex prototypes and high-performance components.

Injection Molding

Elevate production efficiency with rapid, high-quality molded parts and bridge tooling solutions, expertly tailored for large-scale manufacturing and unparalleled product consistency.

Sheet Metal Fabrication

Experience unparalleled adaptability and precision in shaping metal components for diverse applications, harnessing the versatile power of metal forming.

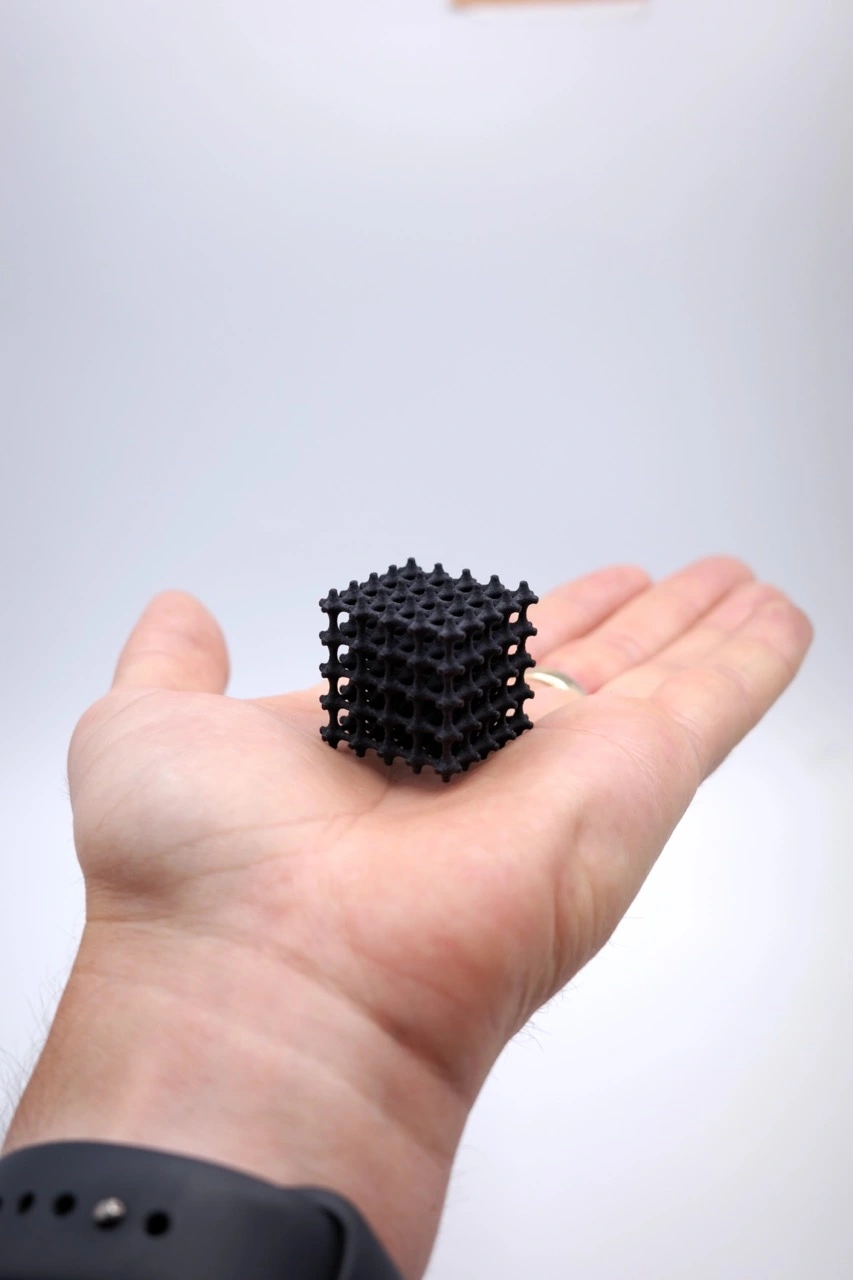

3D Printing

Rapid and adaptable, this technique effectively transforms a wide range of materials into intricate shapes, ideal for pioneering and imaginative designs.

Effortless Access to Scalability

Mucision simplifies scalability with diverse processes, expert teams, and engineers. Trust us to handle your production needs, allowing you to focus on your core business. Our high-quality designations and ITAR registration ensure project success. We prioritize data security with file encryption. Production order services include:

- In-house engineering teams offering process, material, design, cost optimization, and order management with MSAs.

- Quality control procedures like PPAP, control plans, inspections, reports, and advanced metrology equipment.

- CoCs, material certifications, lot traceability, and export restriction management (ITAR/DFARS).

- Thread tapping, hardware installation, and in-house assembly services for box builds and electromechanical assemblies.

Pre-Production Rapid Prototyping

Mucision supports every stage of product development, including the vital prototyping phase that transitions product designs to production-ready status. Our rapid prototyping services enable you to obtain testable components within days. Additive manufacturing advancements have made 3D printing a preferred rapid prototyping method, producing parts quickly and cost-effectively in various metals and plastics.

Mucision offers eight distinct 3D printing processes suitable for prototyping and low-volume production. Besides 3D printing, our rapid prototyping services include CNC machining, sheet metal fabrication, and rapid injection molding. Explore our Rapid Prototyping Service page for more information on each option.

Low-Volume Production

Our low-volume production services bridge the gap between prototyping and full-scale production, adapting to your product’s demand while optimizing the manufacturing process. These services help you gauge market success before investing in high-volume tooling, reducing costs and risks.

Our popular low-volume production options include CNC machining, sheet metal fabrication, urethane casting, and additive manufacturing. These solutions enable rapid market entry and flexibility for design changes. We optimize production using smart batching and parallel processes, while also managing post-processing like anodizing, metal plating, and painting.

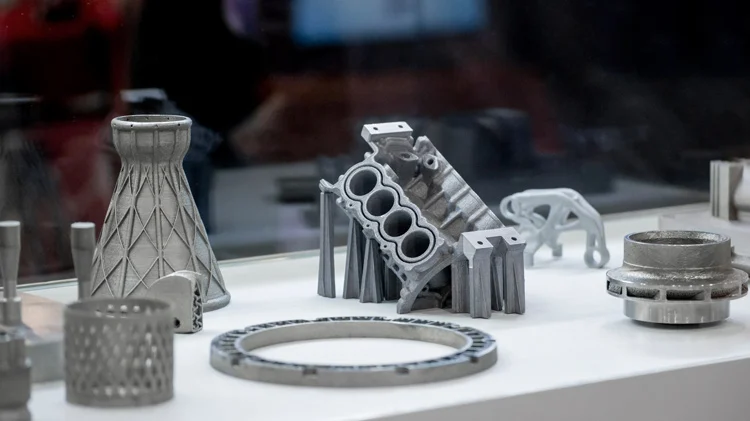

High-Volume Production Service

For full-scale production, our high-volume services cater to your needs. We offer industry-leading methods to produce thousands to millions of parts annually. Our popular high-volume solutions include plastic and metal injection molding, die casting, metal stamping, and extrusion.

Injection molding remains a versatile choice for various applications, with 50+ molding plastics and tolerances as low as ±0.002″. Our metal forming processes, such as metal injection molding, die casting, extrusion, and stamping, enable fast production of precise and complex metal parts. Learn more about each process by visiting the links below.

How to choose Between Production Processes

Selecting the ideal manufacturing process and material is crucial for optimal performance. Our experts can help you choose the best solution for your specific application. While injection molding is a popular choice for lightweight, durable plastic parts, CNC machining and sheet metal fabrication are often preferred for precision metal components with strict material needs. Advanced 3D printing technology offers strong, cost-effective parts for various engineering requirements.

To assist in your decision-making process, we’ve created a table comparing various production paths and processes based on capacity and scalability requirements. Please refer to the following guide for more information:

Production Capabilities Comparison

| Final Production Process | Annual Capacity | Scalability | Validate Early Using : |

| Plastic Injection Molding | 500 – 1,000,000+ | Mid – Very High | Plastic 3D Printing, Prototype Injection Molding, Urethane Casting |

| Metal Injection Molding | 2,000 – 1,000,000 | Mid – Very High | CNC Machining, Metal 3D Printing |

| Metal Casting (Die, Investment, Etc.) | 500 – 1,000,000 | Mid – Very High | CNC Machining, Metal 3D Printing |

| Metal Stamping | 500 – 1,000,000+ | Mid – Very High | Sheet Metal Fabrication, Sheet Cutting |

| CNC Machining | 1 – 100,000 | Low – High | CNC Machining |

Why Choose Mucision?

Boundless Options

Select from an extensive range of material, finish, tolerance, marking, and certification combinations to customize your order.

User Friendly

Enjoy convenient, hassle-free delivery of your parts directly to your doorstep, eliminating sourcing, project management, logistics, and shipping concerns.

Enriched Network

We are ISO 9001:2015, ISO 13485, IATF 16949:2016, and AS9100D certified.