Custom 5-Axis CNC Machining Services

By surpassing the limitations of traditional machining, 5 Axis CNC Machining delivers high-precision, mission-critical parts with unmatched accuracy. Our 5 Axis CNC Machining services enable the creation of custom parts featuring intricate multi-axis complexity, ensuring timely and cost-effective production.

Mucision’s 5-Axis CNC Services

High-Quality Rapid Prototyping and Production Parts

Mucision’s 5-axis machining services boast unparalleled speed and adaptability. Leveraging a diverse array of state-of-the-art 5-axis CNC machines and an extensive material selection, Mucision consistently delivers top-quality 5-axis machined parts.

Our skilled team and advanced manufacturing capabilities facilitate swift design and fabrication of intricate, time-sensitive components. Combining world-class equipment, expertise, and experience, Mucision employs two exceptional setups to produce precise, complex parts.

What is 5-Axis CNC Machine?

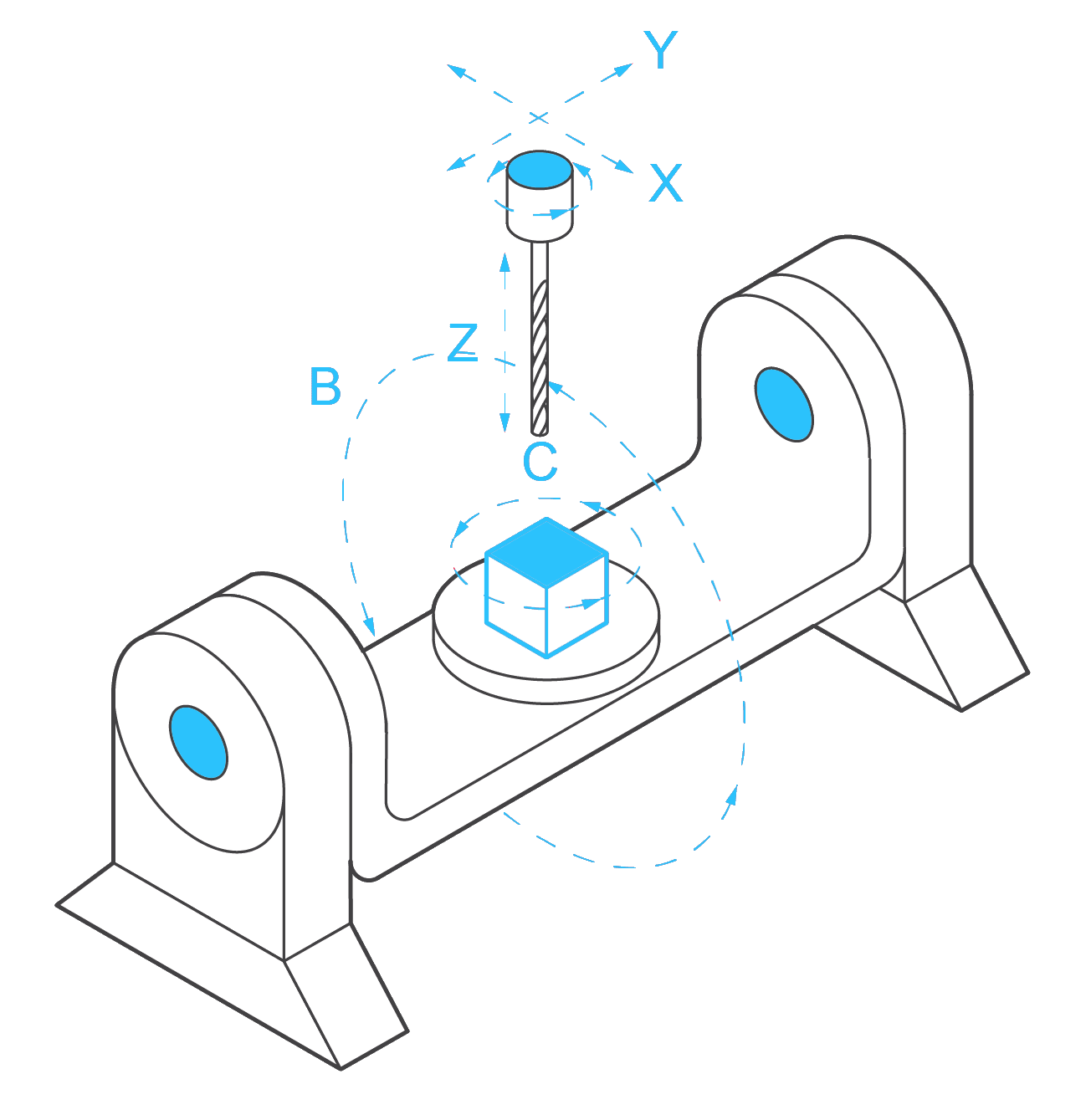

The five axes in 5-axis CNC machines enable increased versatility in tool movement directions. While traditional CNC machines typically operate with X, Y, and Z linear axes, 5-axis machines introduce A and B rotating axes, allowing for multi-directional workpiece manipulation and enhanced precision.

Why Choose Mucision for 5-Axis CNC Machining?

Boundless Options

Select from an extensive range of material, finish, tolerance, marking, and certification combinations to customize your order.

User Friendly

Enjoy convenient, hassle-free delivery of your parts directly to your doorstep, eliminating sourcing, project management, logistics, and shipping concerns.

Enriched Network

We are ISO 9001:2015, ISO 13485, IATF 16949:2016, and AS9100D certified.

Materials for 5-Axis CNC Machining

Additional alloys and tempers are available upon request. We can source to your project specifications. If you do not see your alloy or material listed on our platform, please select “Other” and write in that specific material.

Available Finishes

5-Axis CNC Machining Capabilities

| Description | |

|---|---|

| Maximum Part Size | 4000×1500×600 mm |

| Minimum Part Size | 5 x 5 x 5 mm |

| General Tolerances | Within ±0.002 mm |

| Lead Time | For standard operations, lead times can be as short as 2-3 days, while more complex projects might require up to 2 weeks. |