Why Choose Mucision?

Boundless Options

Select from an extensive range of material, finish, tolerance, marking, and certification combinations to customize your order.

User Friendly

Enjoy convenient, hassle-free delivery of your parts directly to your doorstep, eliminating sourcing, project management, logistics, and shipping concerns.

Enriched Network

We are ISO 9001:2015, ISO 13485, IATF 16949:2016, and AS9100D certified.

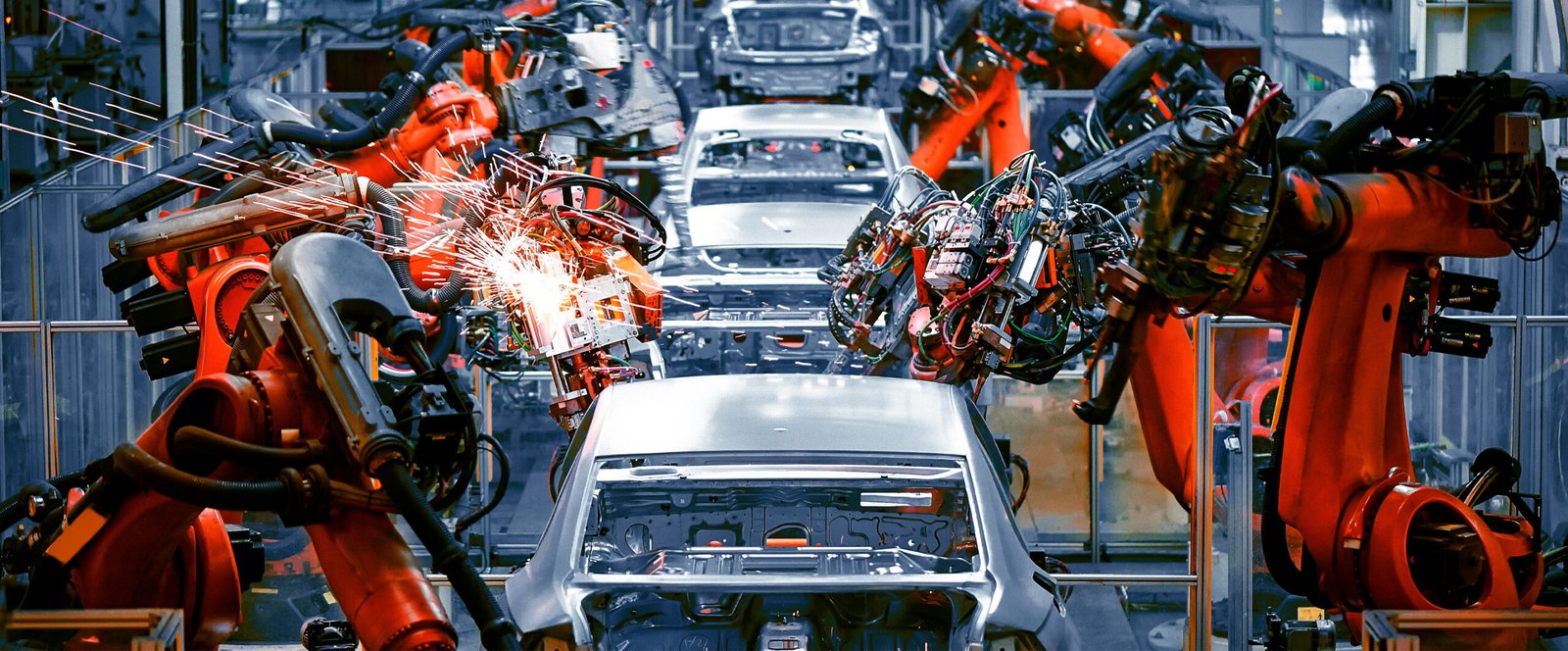

Mucision collaborates with leading automotive manufacturers to streamline their supply chains and adaptively scale their manufacturing capabilities. This innovative approach can be likened to “production capacity-as-a-service” or “just-in-time manufacturing” for the digital era. Top electric car companies and autonomous driving startups have partnered with Mucision to create a highly scalable, on-demand supply chain, accelerating their market entry. Mucision’s expertise spans injection molding, CNC machining, sheet metal fabrication, and 3D printing for the automotive sector, extending to motorcycle and other vehicle manufacturing.

Our Manufacturing Capabilities

CNC Machining

Unlock unparalleled precision and intricate designs with our advanced CNC machining capabilities, perfect for complex prototypes and high-performance components.

3D Printing

Rapid and adaptable, this technique effectively transforms a wide range of materials into intricate shapes, ideal for pioneering and imaginative designs.

Injection Molding

Elevate production efficiency with rapid, high-quality molded parts and bridge tooling solutions, expertly tailored for large-scale manufacturing and unparalleled product consistency.

Sheet Metal Fabrication

Experience unparalleled adaptability and precision in shaping metal components for diverse applications, harnessing the versatile power of metal forming.

We Help Transform Your Ideas

from Prototypes to Production

① Prototyping

The prototyping stage commences the product development process. At this stage, designers conduct thorough testing of the conceptual designs, implement necessary modifications to enhance functionality, and select the suitable materials for the fabrication. This approach ensures that the resulting prototype not only meets but exceeds performance expectations.

② Engineering Validation and Testing

Rapidly and effectively refine performance-driven iterations to ensure prototype functionality adheres to established standards. At Mucision, we specialize in creating functional prototypes that simplify risk identification and mitigation during the design process, guaranteeing the final prototype fulfills all performance and functional criteria.

③ Design Validation and Testing

④ Production Validation and Testing

Pre-production Validation Testing (PVT) marks the ultimate phase prior to mass production initiation. This stage focuses on preparing the design for large-scale manufacturing utilizing advanced quality control measures and high-grade capabilities. At Mucision, our collaborative approach ensures your production objectives are met, incorporating your feedback and facilitating final design modifications for peak manufacturing efficiency. Moreover, we assist in establishing the product supply chain during this crucial period.

⑤ Mass Production

Following product testing, mass production commences, focusing on the large-scale fabrication of end-use components. At this critical stage, prompt delivery of final products and stringent adherence to quality standards are paramount. Mucision excels in mass production through a strategic blend of cutting-edge manufacturing equipment, sophisticated processes, and skilled engineering expertise.